BEST IN CLASS ACCESSIBILITY.

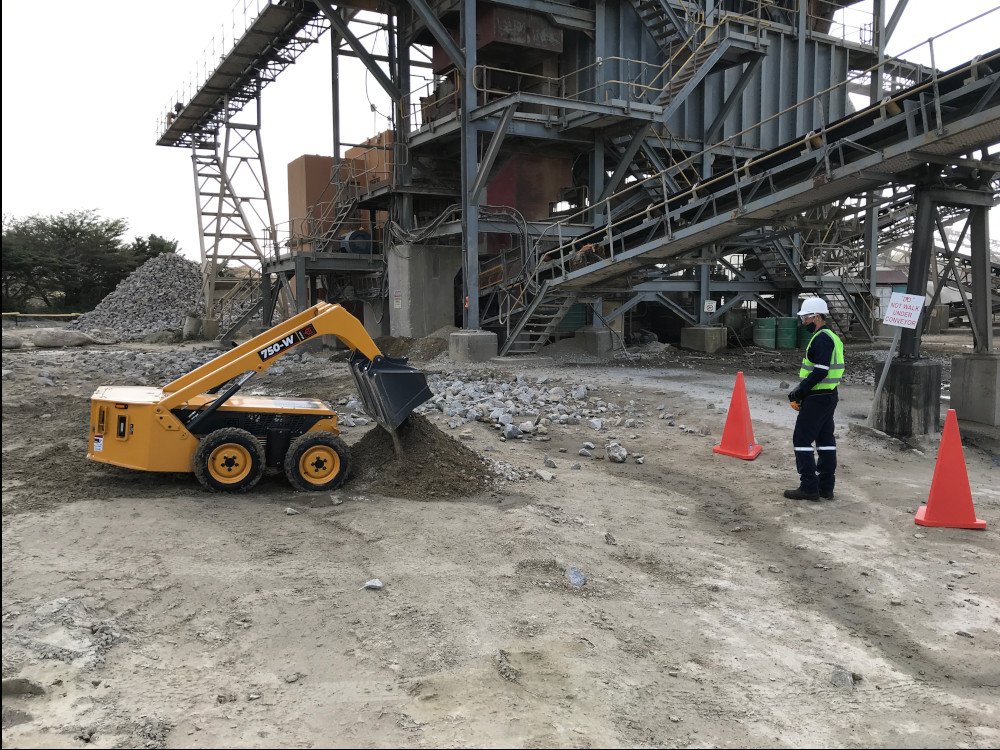

The purpose designed Remote Skidsteer combines simplicity and functionality in a robust, ultra-low package to offer a complete solution for under-conveyor cleaning. Packed with features to enhance operational efficiency and operator safety, the low-profile design manoeuvres comfortably in confined spaces where headroom is limited.

Designed from the ground up, the low-profile design is exceptionally stable due to the low centre of mass, while the intuitive remote-control system allows for effortless operator navigation, enhancing the operator’s safety.

Loaded with these features:Unparalleled packaging provides best in class accessibility for maintenance, and quick and easy servicing. The optional quick-attach device and additional auxiliary hydraulic functions present a great variety of attachments, both static and driven. The Remote Skidsteer is driven by four independent wheel drive motors and a spring-applied wet parking brake on all four wheels.

Radio control with intuitive operation offers many safety features. These include audible warnings, limp mode or restricted operation and if necessary, automatic shutdown.

The fuel efficient 3 cylinder naturally aspirated engine and load sensing hydraulic drive and work functions provide exceptional fuel efficiency, reliability and long component life.

Fully programmable control system using ETT’s CAN-BUS technology. This allows features such as engine stall prevention, and automatic fast commute, among others.

The efficiency of the diesel engine offers eight-hour run time, with an optional long range fuel tank available for 12-hour continuous operation.